Portali Internazionali

Mappa - Via Corte 1

Alimec: Innovation and Customization at the Core of Pastry Production

Alimec: Innovation and Customization at the Core of Pastry Production

In recent years, Alimec has established itself as a leader in the design and realization of automated and semi-automated solutions for the production of sweets. From a wide variety of desserts ranging from classic cakes and muffins to small cakes, magdalenas, doughnuts, and savoiardi, the company has highlighted customization, technological innovation, and customer satisfaction as the pillars of its business.

Alimec stands out for offering a vast range of customization options for each individual product. Each sweet can be made with a specific design, from the simplest and most essential to the most complex and articulated. It can be mixed with one color or a combination of two colors, using cupcake liners or oiled in a pan. Moreover, the dough can be enriched with a variety of ingredients, such as dried fruit, chocolate, or spices, according to customer preferences. This level of versatility makes Alimec's facilities ideal for a wide range of applications.

Various Types of Topping

Beyond the customization of the product itself, Alimec's facilities can distribute various types of toppings, such as granulated sugar, chocolate drops, and raisins. These ingredients can be added before or after baking, depending on the client's needs. Alimec also offers the possibility to decorate or fill the products after baking, adding an additional level of customization.

Customer Satisfaction and Technological Innovation

Alimec's goal is to meet the needs of its customers, offering innovative and customized solutions. The company's cutting-edge technology allows for the automation and increase of the production process, improving efficiency and product quality. Thanks to its expertise and competence, Alimec has successfully designed facilities all around the world, making it an ideal partner for anyone looking to improve their production process.

Unmolding and Inverting System

Alimec also offers an automatic facility for the production of oiled products and those in cupcake liners, equipped with an advanced unmolding system. This facility is capable of handling medium to high production and offers a series of useful functions, such as an electronic display for data and recipe storage, a quick-release system for the tool to speed up format change, and a coded sensor for tool recognition according to the selected recipe. Furthermore, the inverter with belt rotation managed by a brushless motor ensures absolute and accurate control during product pickup and deposition.

For further information, you can contact Alimec via the following email addresses:

- General: alimec@alimec.com

- Sales: sales@alimec.com

- Technical Support: tech@alimec.com

- Administration: amm@alimec.com

Alimec is located at Via Corte, 1 36030 Valli del Pasubio (VI), Italy. Tel: +39 0445 662600, Fax: +39 0445 662601.

Alimec offers innovative and customized solutions to enhance the production of sweets. Whether it's cakes, muffins, doughnuts, or any other type of sweet, Alimec has the right facility for you.

In recent years, Alimec has established itself as a leader in the design and realization of automated and semi-automated solutions for the production of sweets. From a wide variety of desserts ranging from classic cakes and muffins to small cakes, magdalenas, doughnuts, and savoiardi, the company has highlighted customization, technological innovation, and customer satisfaction as the pillars of its business.

Alimec stands out for offering a vast range of customization options for each individual product. Each sweet can be made with a specific design, from the simplest and most essential to the most complex and articulated. It can be mixed with one color or a combination of two colors, using cupcake liners or oiled in a pan. Moreover, the dough can be enriched with a variety of ingredients, such as dried fruit, chocolate, or spices, according to customer preferences. This level of versatility makes Alimec's facilities ideal for a wide range of applications.

Various Types of Topping

Beyond the customization of the product itself, Alimec's facilities can distribute various types of toppings, such as granulated sugar, chocolate drops, and raisins. These ingredients can be added before or after baking, depending on the client's needs. Alimec also offers the possibility to decorate or fill the products after baking, adding an additional level of customization.

Customer Satisfaction and Technological Innovation

Alimec's goal is to meet the needs of its customers, offering innovative and customized solutions. The company's cutting-edge technology allows for the automation and increase of the production process, improving efficiency and product quality. Thanks to its expertise and competence, Alimec has successfully designed facilities all around the world, making it an ideal partner for anyone looking to improve their production process.

Unmolding and Inverting System

Alimec also offers an automatic facility for the production of oiled products and those in cupcake liners, equipped with an advanced unmolding system. This facility is capable of handling medium to high production and offers a series of useful functions, such as an electronic display for data and recipe storage, a quick-release system for the tool to speed up format change, and a coded sensor for tool recognition according to the selected recipe. Furthermore, the inverter with belt rotation managed by a brushless motor ensures absolute and accurate control during product pickup and deposition.

For further information, you can contact Alimec via the following email addresses:

- General: alimec@alimec.com

- Sales: sales@alimec.com

- Technical Support: tech@alimec.com

- Administration: amm@alimec.com

Alimec is located at Via Corte, 1 36030 Valli del Pasubio (VI), Italy. Tel: +39 0445 662600, Fax: +39 0445 662601.

Alimec offers innovative and customized solutions to enhance the production of sweets. Whether it's cakes, muffins, doughnuts, or any other type of sweet, Alimec has the right facility for you.

- News

-

Termina il... 18-05-2024

ALIMEC

Ingrandisci Mappa...

Richiedi Informazioni

Vai alla scheda attività

- Via Corte 1 Valli del Pasubio - 36030 (Vicenza)

- +39 0445662600 Chiamami Chiamami

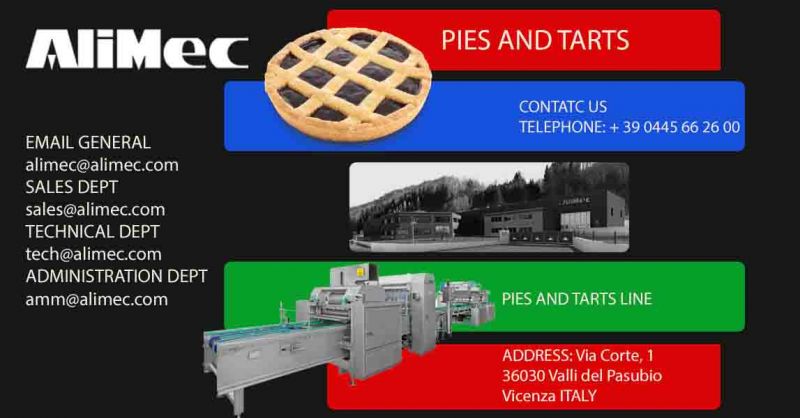

- ALIMEC - Via Corte, 1 - Cap 36030 - Valli del Pasubio (VI) - ITALY - PHONE +39 0445 662600 - FAX +39 0445 662601 - EMAIL CONTACTS - GENERAL - alimec@alimec.com - SALES DEPT - sales@alimec.com - TECHNICAL DEPT - tech@alimec.com - ADMINISTRATION DEPT - amm@alimec.com

- Vai al sito

Richiedi Informazioni

(registrazione richiesta)

Vai alla scheda attività

Ultimi annunci da ALIMEC

https://www.sihappy.it/contenuti/inserzioni/16966/305063/customized-solutions-made-in-italy-to-production-of-any-type-of-sweet.jpg